Beforehand, Kaizen is a practice of continuous improvement. It focuses on achieving improvement in all aspects in an organization through standardizing processes, eliminating waste and involving every member in an organization in achieving improvement. In other words, it means, excluding no one from the top level management as managers, Chief Executive Officer (CEO), and supervisors to the low level management as workers, aimed at customer-total quality care and quality improvement.

The foundation of Kaizen Umbrella concept has many elements, as following:

- Customer orientation means to satisfy the customer needs and consider one of the essential success component and encourage worker towards customer satisfaction.

- Total Quality Control is considered one of the tools for quality improvement in health care and it is very important to understand the process and how is working.

- Robotics and automation – automation can be a big help, but it’s not the absolute solution in every case

- Quality circles to engage the employees to attract their attention and keep them interested in the workplace

- Total Productive Maintenance (TPM) by maintaining the machine in the highest production efficiency to maximize performance of production

- Kanban methodology that used in the production process and the main purpose is to provide information about the need for all materials during the production.

- Just in time (JIT) that means that means parts and supplies must be delivered just as needed in quantity needed, so, that improve effectiveness of a company by reducing inventory an, eliminating costly and wasteful material through production of good.

- Quality improvement means Continuous improvement and is considered the main key to success

- Quality improvement means root of continuous improvement through apply it to joints of the organization whether, workplace, people, products, machine and so on and is considered the main key to success.

- Zero defect is an approach aimed at eliminating faults and errors.

- Small-group activities that will be a big help to boost teamwork and it will increase the efficiency of workers’ performance to work together and enhance their skills towards their tasks in the workplace.

- Productivity improvement is the effect of the scheme by reducing the materials and labor to increase the output for the same quantity of input.

- New product development is wanted to keep us in our business working smoothly and remain us in the business

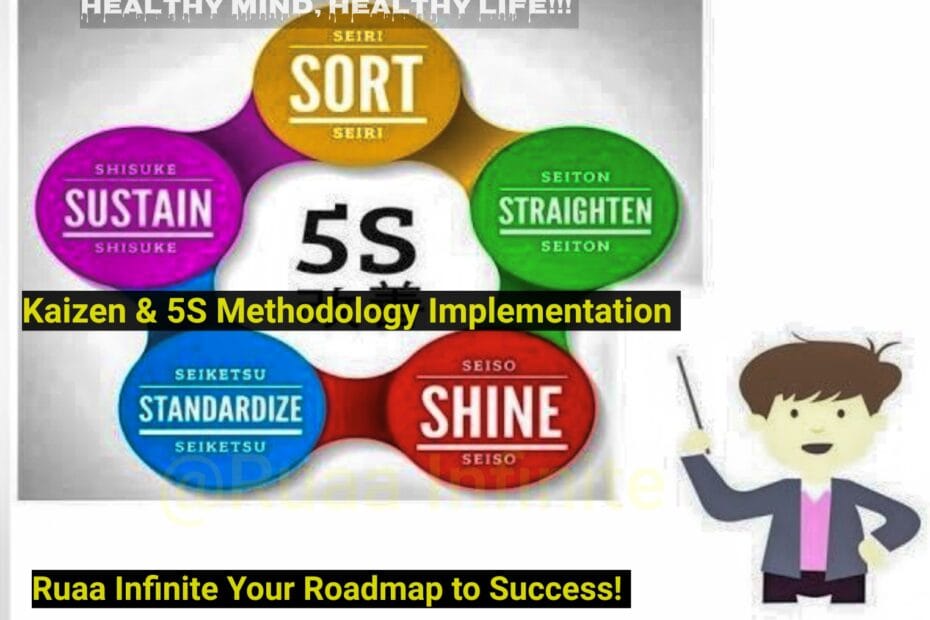

- Discipline in the workplace means using 5S method everywhere, which are represented as below:

• Seiri – tidiness / sort Keep all garbage and irrelevant materials from the workplace

• Seiton – orderliness/set in order Organize whatever is needed in the workplace in the right place to keep the neat way and store things easier.

• Seiso – cleanliness/ shine Keep work clean, any person acts as a cleaner

• Seiketsu – Standardize Make standardization to keep clean and standardize the workplace or things.

• Shitsuke – discipline/ sustain 5s practice on a regular basis as a sign of commitment.

As a matter of fact, by making workers apply Kaizen in the workplace, it will be a huge success to facilitate the work becomes easier and make improvement. So, with 5s / Kaizen gains on the production floor, it can be easily accessed without obstruction, for instance: –

- Waste disposal becomes easy and habitual

- The risk of accidents becomes very minimal and the security/safe level becomes high.

- Workers’ morals are improving, as they said the thinking worker is a productive worker.

- Environmental pollution is eliminated to the extent maximum.

- Machines, equipment and tools become easily promptly identifiable.

- Income will increase and the company or organization will make more gains at lower cost.

On the other hand, Kaizen implemented by 5S technology at Mory Industries Inc. Since the start of the company’s establishment until today.

Kaizen has been implemented since the foundation of the company to date and the data is documented every year. Improvements always refer to 5S technology. To maintain the company’s performance, Morey Industries applied Kaizen to the entire workplace, and the implementation of 5S terms in Mory Industries Inc. wasn’t just only in the plant but also in the office.

This company is a Japanese manufacturer, 5S and also Kaizen is preferred for general use in manufacturing companies. In addition, quality control is an important point of business for this company, especially in innovation.

Mory Industries Inc. has recently expanded its business to other countries, namely Indonesia and Thailand. The goal of establishing PT. Mory Industries Indonesia will provide stainless steel tubes to the auto parts market which has developed greatly in Indonesia and it is under extreme Japanese observation that’s still relying on Japanese Management. Mory Industries Inc. sells Stainless steel products are in various types such as tube, flat bars, round bars, corner bars, etc. In addition, work is still progressing in terms of selling building materials products, especially in steel.

Innovation and technology are considered the cornerstones of any company. So, if the company wants to remain competitive, it must encourage using the innovation, due to Modern innovation makes moving money around be much easier than it used to be. Therefore, the company noted that there is no way to move forward except through innovation, and that the company has applied Lean tools in stainless steel, and in order to compete, Mory Industries Inc. would have to seek ever-increasing technological innovations to raise productivity, increase outcomes and reduce prices. For instance, many companies avoid manufacturing stainless steel as raw material, because it is very difficult. Mory Industries Inc. gets this great opportunity, and conducts active research on manufacturing technology. As a result, Mory Industries Inc. in successfully developing her business, expanding her market and also reminding her of higher value.

It was also noticed that Kaizen through 5S technology was applied in Mory Industries Inc. since the start of the company’s establishment until today. So, they divided the Kaizen type into 10 types, which are path distance, capture distance, weight reduction, difference directions, zig-zag reduction, mental load reduction, straight line taking of product, uniform positioning, reduced add-ons and reduced packaging. So, Mory Industries Inc. has increased its productivity by applying those techniques into sustainable practices as following:

- It is included in reducing the type of overtime for Kaizen and refers to 5S – Seiri which is Keeping all garbage , irrelevant materials and having a good look at the workplace and identifying unnecessary items it helps to merge two documents into one database

- warehouse tools map has been made between the closets to smooth workers pick the required tools it refers to path distance Kaizen type and also 5S – Seiton which is organizing the things in the right place.

- changing the shape of the production waste site it refers to the path distance, capture distance, zigzag reduction type of Kaizen and also 5S – Seiso which is keeping the workplace clean.

- manufacture barcode and color system is one of the improvements included in uniform placement type of Kaizen type of Kaizen and also indicates the 5S – Seiketsu that standardizes objects, as well as also in visual management and it has been applied for almost 10 years.

- bulletin board of efficiency machine indicates the mental load reduction Kaizen type and also 5S technique Shitsuke which is made the workers face discipline. This bulletin board really assists the operator in charge of the machine and will also affect the company’s profits when it really reaches the goal.

Nothing can change, or will change, without technological innovation and a little bit innovation always gives it a financial impact on the company. From this study we can see that Mory Industries Inc. Kaizen’s result is always turned into money. The goal is to make the workers easily understand the benefit of the improvements that have been made.

Eventually, my perspective is, as more and more business in every sector take part in health and safety management and adopt more practices, mainly to save costs and generate more profit, and beyond any doubt, training of 5s/kaizen will be improved our productivity, improved our morality and saved us unnecessary cost of bills

Through an incessant plant accident. It’s our hope that our ongoing practice of 5s and kaizen would land us at our desirable peak.

Final Note and Call to Action:

If you found value in this deep dive into this topic, please give us a thumbs up! For more insightful content and opportunities, subscribe to our YouTube channel @RuaaInfinite and visit our website at https://ruaainfinite.com.

Join us on this journey of growth and discovery. Your support means the world to us.

Stay tuned for our next tech showdown. Thanks for visiting, and until next time, stay secure, stay informed, and stay alert!

Note: Hope My message finds you well in good health and condition

Have a wonderful day everyone!

Best Regards,

Waleed R.

🌟 Special for Teacher Waleed’s students! 🌟

Dear students,

Great news! 📚 You can now download the Speak Out A2 book directly from our post in Ruaa Infinite – English Students Hub:

👉 https://ruaainfinite.com/elevate-your-english-how-to-use-the-english-students-hub-for-success/

✅ Perfect to boost your speaking and listening

✅ Step-by-step practice to build your confidence

✅ Free for all Teacher Waleed’s students!

📥 Download now and start practicing today! 🔥🎤

Let’s keep learning together and make your English journey smoother and faster! 🚀✨

With best wishes,

Teacher Waleed 🌿

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/es-AR/register-person?ref=UT2YTZSU